We are your full-range service provider for thermoplastic composites.

Your competent partner for composite components, manufacturing processes, and tool design

We are at your side as a competent partner if you want to expand your product portfolio with new composite components or replace conventional components with new lightweight structures in order to increase the performance of your applications. We offer you custom-fit FRP solutions for all industries and, on request, full-service engineering: from idea through technology development to implementation for series production. The hurdles for the use of new fibre-reinforced (FRP) components are usually lower than expected and can be easily overcome with strong partners.

The advantages and potentials are obvious:

- Reduce the weight of your components

- Increase the stiffness and load-bearing capacity

- Improve the crash and failure properties of structural elements

- Utilise the advantages of thermoplastic composites, such as high material damping, corrosion resistance and a long service life in your products

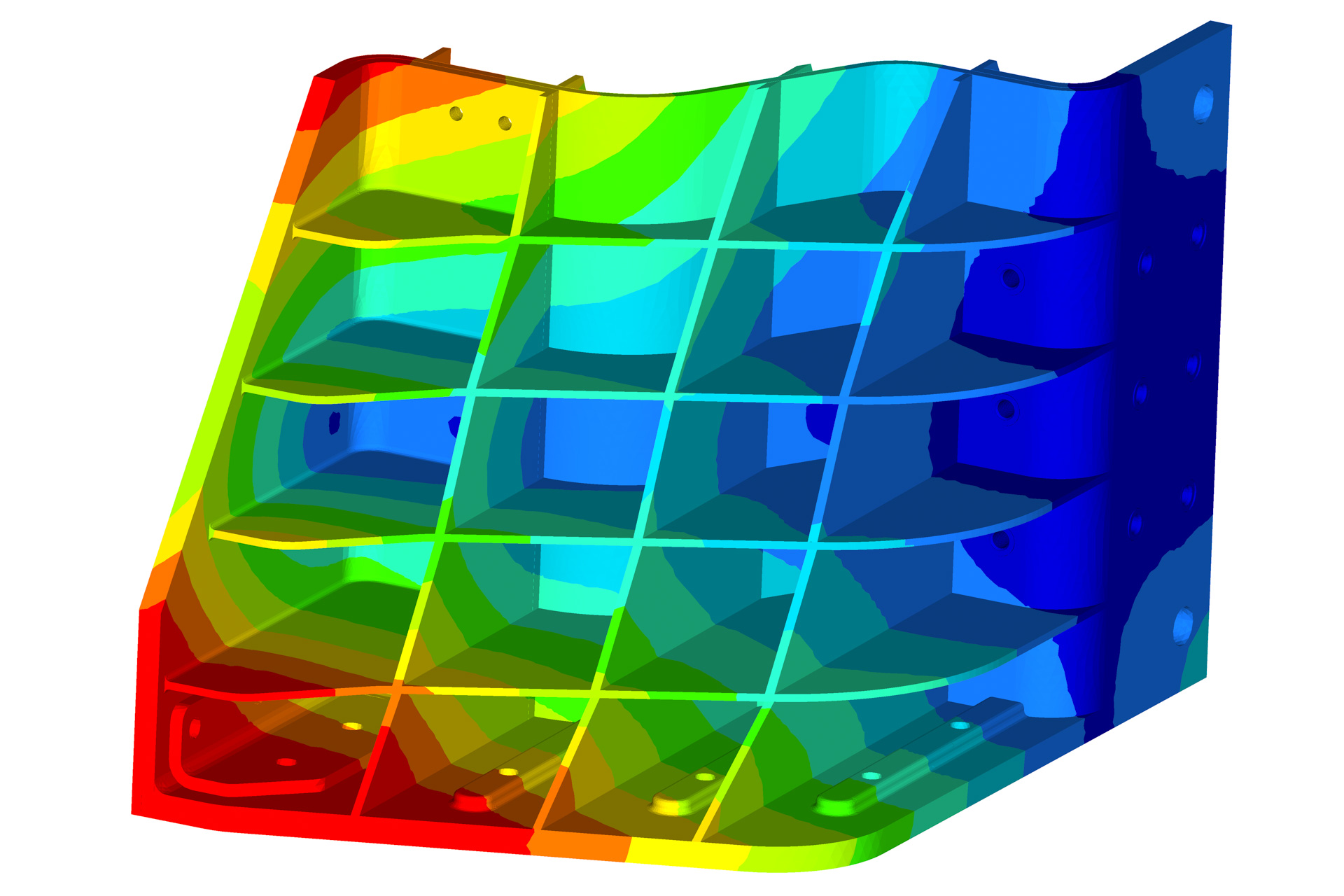

- Reduce your development costs through the latest simulation methods with regard to component optimisation and design

- Development and production of semi-finished products suitable for your applications

- Development of integrated manufacturing processes based on fibre-reinforced thermoplastics

- Significantly reduce process steps, manufacturing stages and costs

Our certified quality management system reflects our high quality standards

Our quality management system is based on the principles of thermoPre ENGINEERING GmbH on quality, customer satisfaction and occupational safety. It meets the requirements of DIN EN ISO 9001: 2015 and has been certified by TÜV SÜD since 2021.

Reduce the mass of your components with new materials!

thermoPre ENGINEERING offers you custom-fit FRP solutions for your industry. We incorporate innovative concepts as early as the design and layout stage of your components. The targeted use of reinforcement structures in load direction enables the development of a component that is optimally adapted to real loads with the highest degree of lightweight construction and minimal material usage. This enables the moving components in your application to achieve significantly higher rotational and cycle speeds due to the lower mass moment of inertia.

For every requirement in the field of fibre-reinforced thermoplastic composites, we can present you with the most suitable current solution approaches and adapt them for your project.

Our services include:

Load-adapted semi-finished products

Development, production and distribution

Material cards

Characterisation of the complex material behaviour of lightweight materials

Dimensioning

Development and application of new calculation methods for the optimal design of fibre-reinforced plastic components

Components

Holistic view of component manufacture: from development and design through the process chain and component testing to prototypes and pre-series products

Recycling

Recycling of thermoplastics with and without fiber reinforcement and technical elastomers

The best possible combination of materials makes all the difference!

- Glass fibres (GFRP)

- Carbon fibres (CFRP)

- Aramid fibres (AFRP)

- Acrylonitrile butadiene styrene (ABS)

- Polyamide (PA)

- Polybutylene terephthalate (PBT)

- Polycarbonate (PC)

- Polyetherimide (PEI)

- High-density polyethylene (HDPE)

- Low-density polyethylene (LDPE)

- Polymethyl methacrylate (PMMA)

- Polyoxymethylene (POM)

- Polypropylene (PP)

- Polyphenylene sulfide (PPS)

- Polystyrene (PS)

- Polyester elastomers (TPC-ET, TPE/TPV, etc.)

- Thermoplastic polyurethane (TPU)

- Structural integration, e.g. integration of add-on parts and inserts

- Material-specific functionalisation, e.g. elastomeric or metallic functionalisation

- Sensory functionalisation, e.g. structural health monitoring, strain measurement

- Functionalisation of compounds by means of fibre reinforcement, adhesion promoters, flow improvers and thermal stabilisation

We combine traditional technologies into efficient processes.

- Thermoforming

- Impact extrusion

- Injection moulding

- In-mould injection moulding

- Multi-component injection moulding

- Thermoplastic foam injection moulding

- UD tapes (unidirectional continuous fibre-reinforced tapes)

- Organic sheets with load-adapted superstructures

- Hybrid rovings

- Glass mat reinforced thermoplastics (GMT)

- Long-fiber-reinforced thermoplastics (LFRT)

Strong partnerships ensure you have access to the latest technologies.

In order to reliably use new types of composites in series production and compete on the market, know-how about traditional and alternative materials, characteristic values and production technologies is necessary and in demand. For optimal results, it is necessary to know the behaviour of the composites exactly. What properties do they have, how can they be processed in the best possible way, which process parameters are decisive for consistent quality?

thermoPre ENGINEERING therefore maintains close contact with regional research institutions and is integrated into a regional R&D network. We are a member of Composites United e.V., the international network for fibre-based lightweight construction.

With us, you can enjoy comprehensive expertise. We have our finger on the pulse. Without detours, you receive everything from a single source.

Visit our lectures and events

We cordially invite you to get to know us personally, be it at trade fairs, conferences or in-house events. Come and talk to us! The following next opportunities are available for you: