Embark on new paths with us with innovative and ultra-lightweight materials.

Our project process: transparent, dynamic and goal-oriented

01

Contact us

Our team is looking forward to your new project. Call us or send us your enquiry by e-mail. We would also be happy to visit you in person to discuss your project or project idea on site. An assessment of the actual component is advantageous for our further course of action.

02

Your product specifications

At the beginning of the project, we analyse the application area and your specifications. Important performance data and framework conditions we require include:

- Application area with relevant parameters, such as temperature, exposure to chemicals, weather conditions, etc.

- Available installation space incl. all add-on parts or inserts

- Real static and dynamic load data

- Special requirements in terms of weight, corrosion resistance, high-temperature suitability, etc.

- Manufacturability

- Quantities and cost specifications

In order to exploit the full potential of fibre-reinforced plastic composites, a 1:1 substitution of the component and thus of the properties of the conventional materials (such as metals) is not expedient. Knowing all the real loads and framework conditions, the anisotropic material properties of the FRP materials can be fully exploited and ideal results can be achieved.

03

Customised offer

You will receive a customised offer for your project based on the specifications and the jointly defined goals. We will be happy to discuss the individual work items and the time frame with you.

04

Feasibility check

Based on your specifications with the real component requirements, our experienced engineers assess the feasibility and practicability of your project. In the process, various solution approaches are developed, analysed, and evaluated. These can be used to estimate how your framework conditions can be fulfilled. In addition, we will present you with the most suitable process for the manufacture of your component, depending on the size of your series. As a result, we present you with what we consider to be the optimal solution for the realisation of your project.

05

Material development

If the materials are not pre-defined in your specifications, we take over the complete material development, taking into account the performance specifications of your component, the planned use and the cost framework. It is our intention to use the right material in the right quantity at the right place.

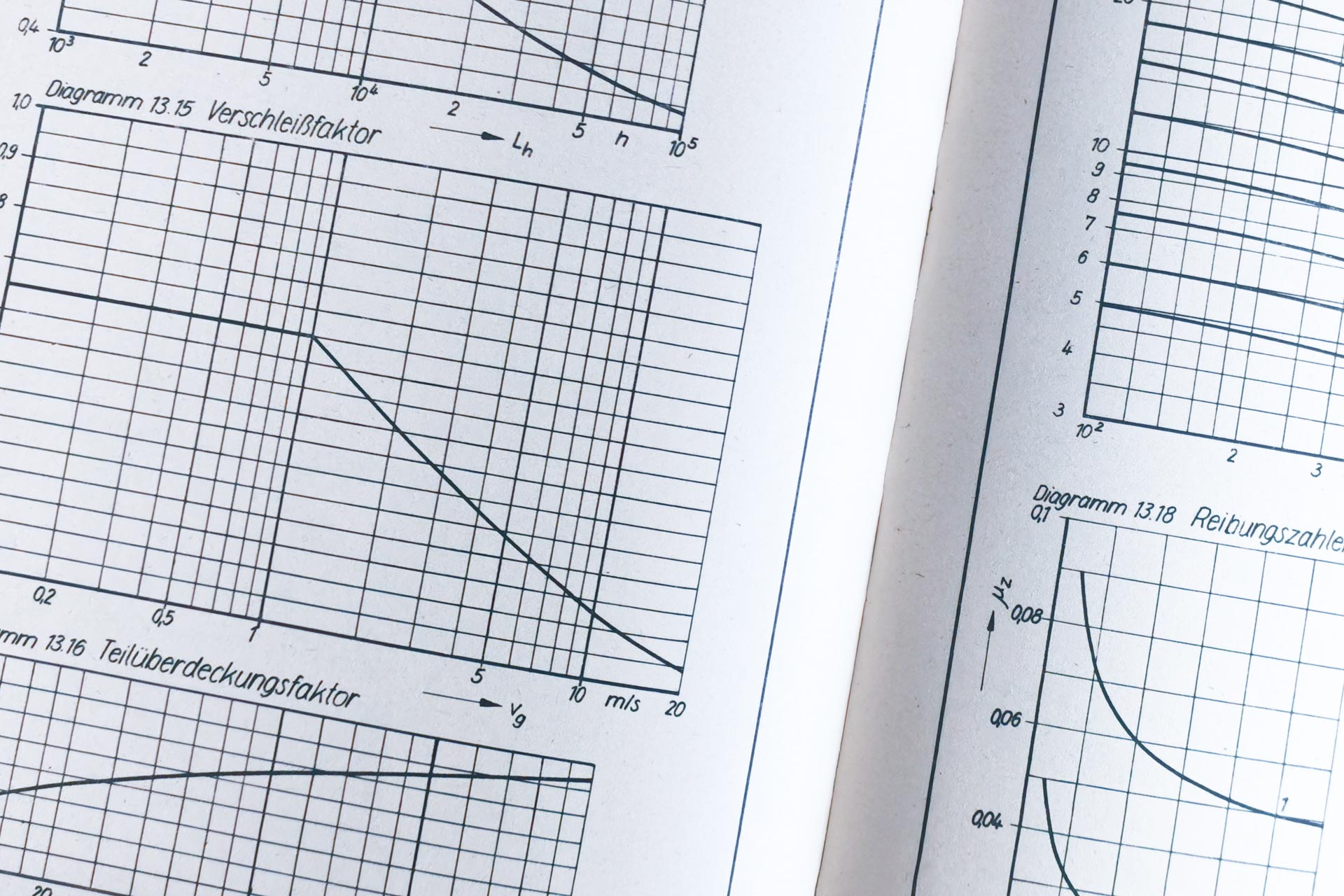

In this development step, the materials and the material parameters for the thermoplastic semi-finished product are selected according to your component requirements and different variants are compared. This concerns, for example, the reinforcement fibre and matrix type, the reinforcement effect (e.g. UD), the fibre volume content, the layer structure, etc. The comparison of the characteristic values determined in static and dynamic test methods results in the preferred material variant with regard to stiffness and strength.

06

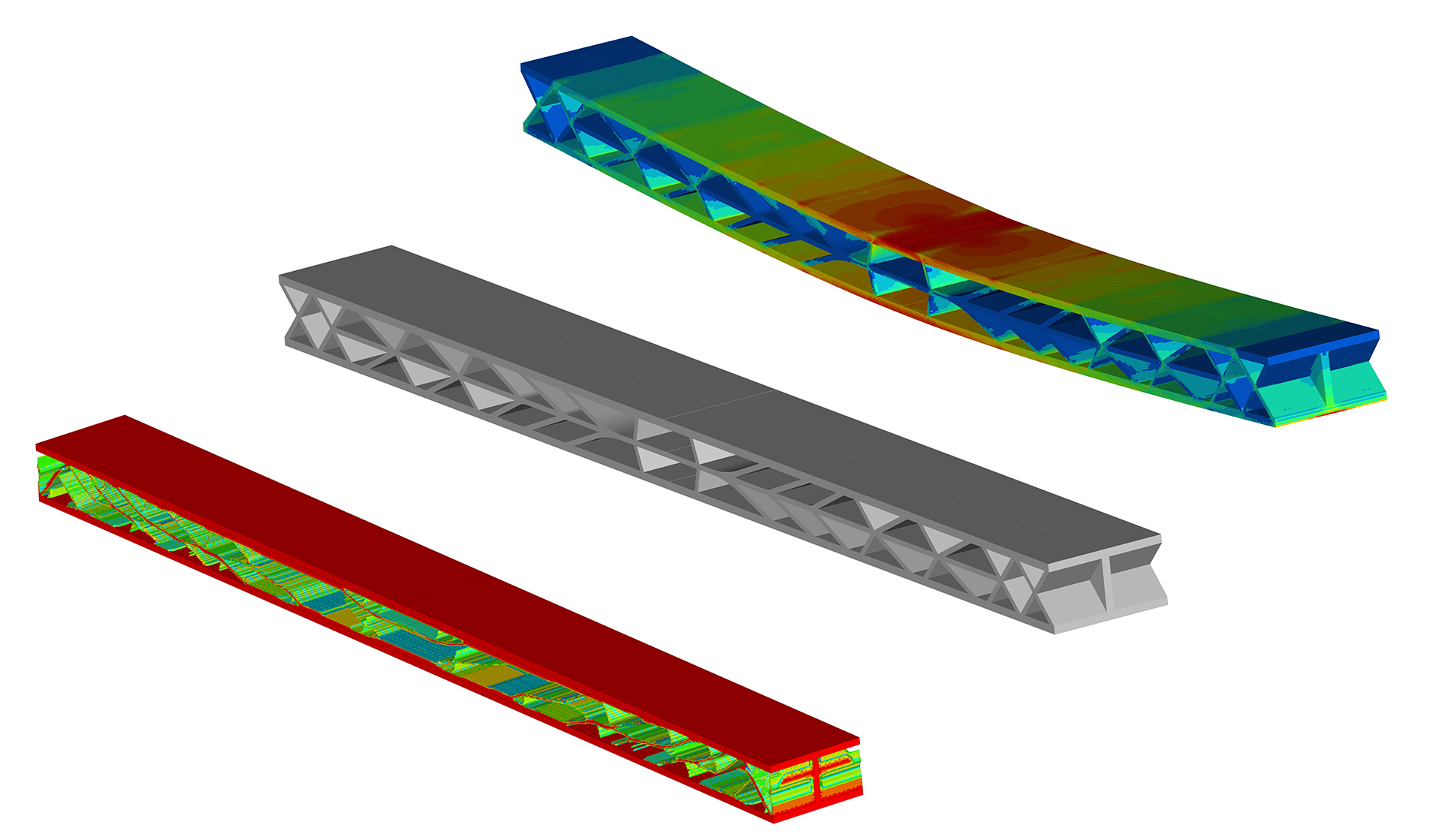

Component calculation and design

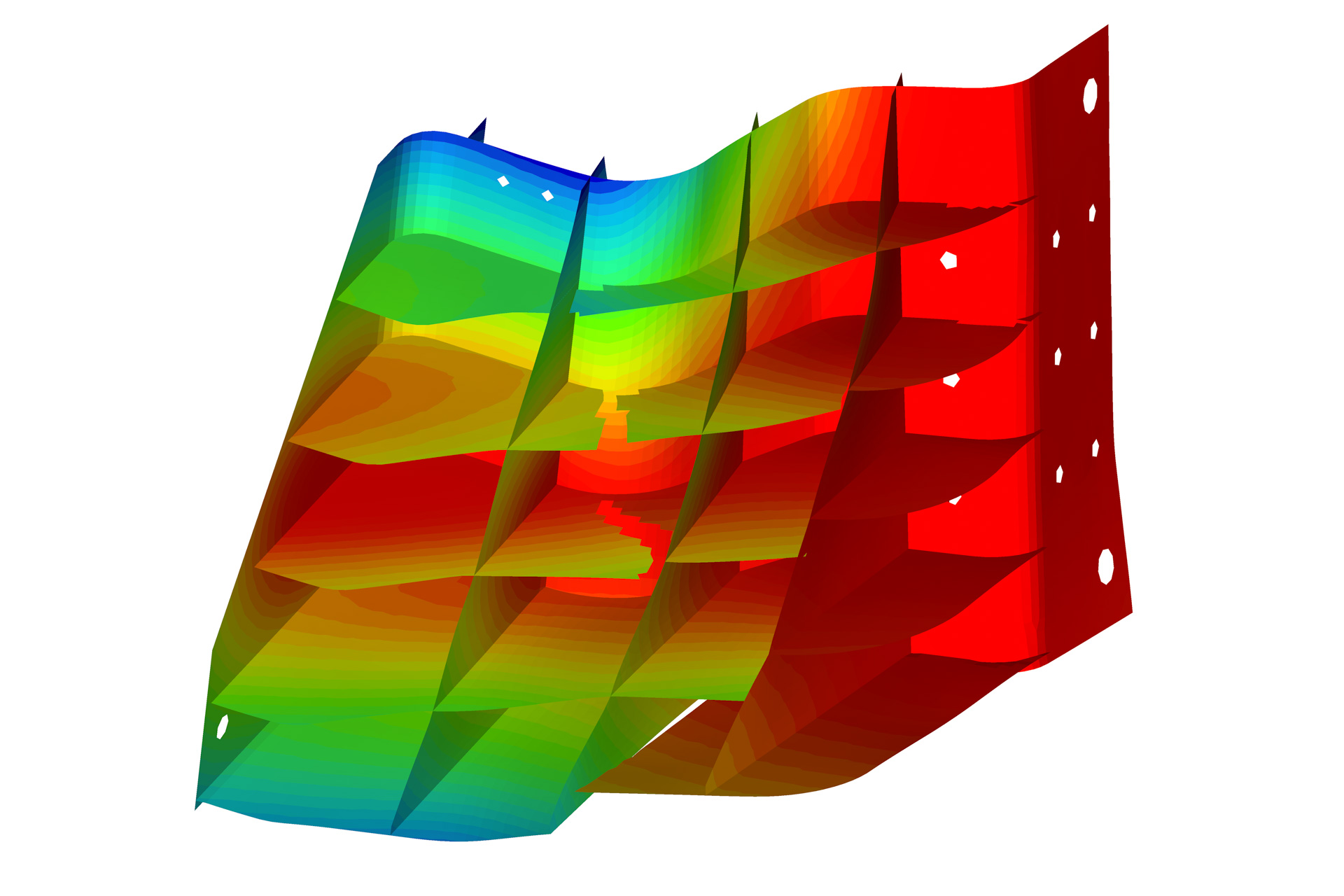

We carry out the geometric and material design, calculation and layout as well as dimensioning for your component. Using the finite element method, we develop a component concept that meets the load specifications.

Using various numerical tools, such as topology and topography optimisation, an optimal solution for your component is developed as a CAD model, including the following points:

- Development and validation of material cards

- Material optimisation (layer structure, fibre orientations, reinforcements, etc.)

- Optimised component structure and geometry

- Detailed solutions suitable for production

07

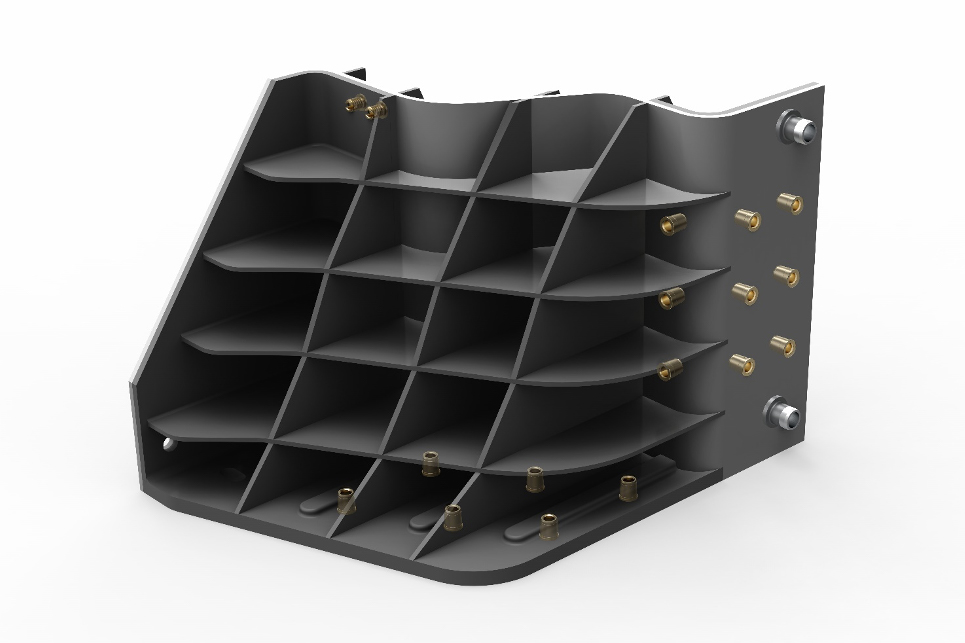

Component design

Based on the component design, a constructive itemisation of the preferred variant developed is carried out. Stiffness, strength and manufacturing restrictions as well as toolmaking requirements are taken into account and transferred into a CAD model suitable for manufacture. We also create production drawings on request.

08

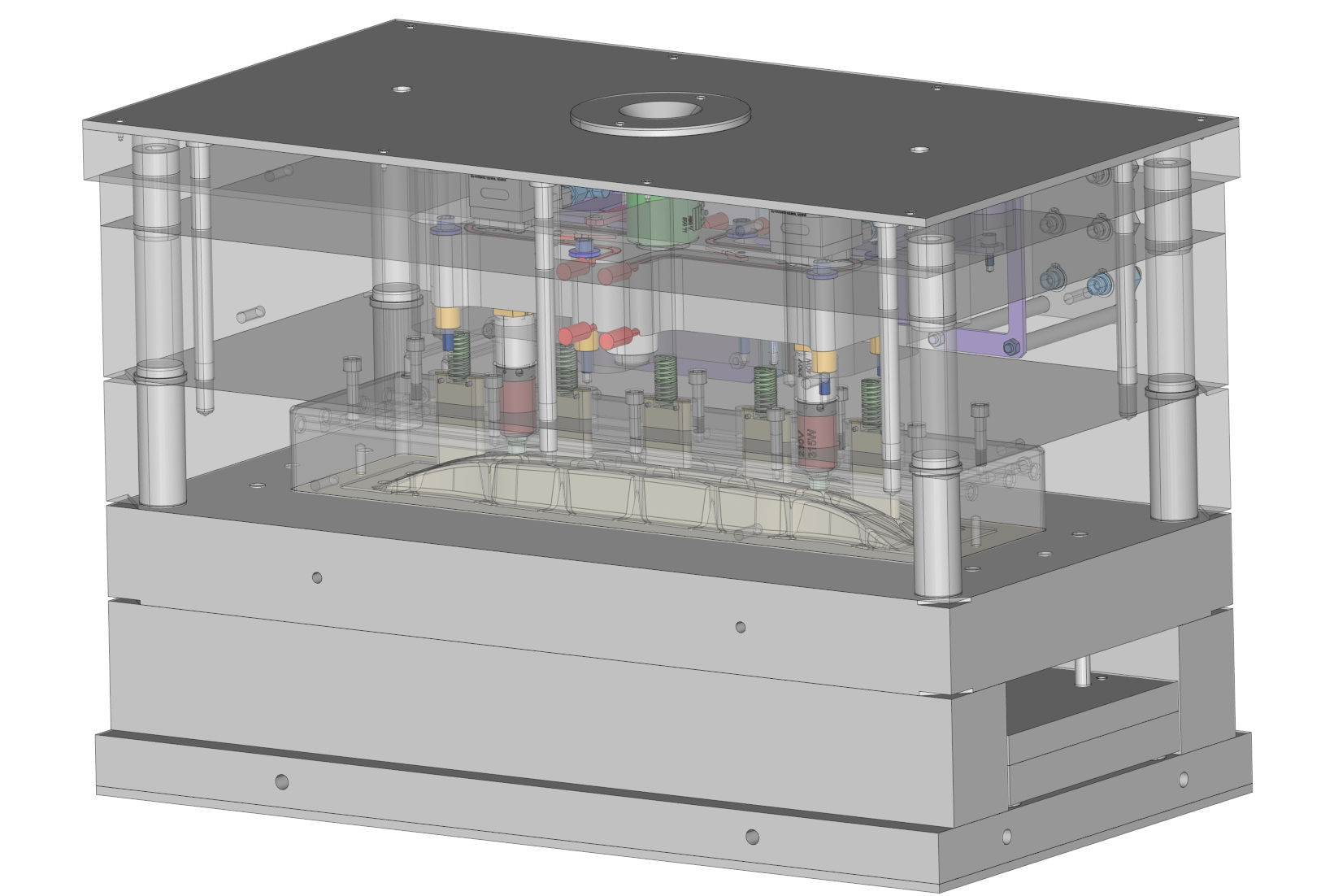

Tool design

Depending on the selected manufacturing process, we carry out the tool design for a prototype tool. In coordination with you, we are happy to take over the selection and commissioning of a competent external partner in the region for the tool manufacture, including technical support for the tool construction.

09

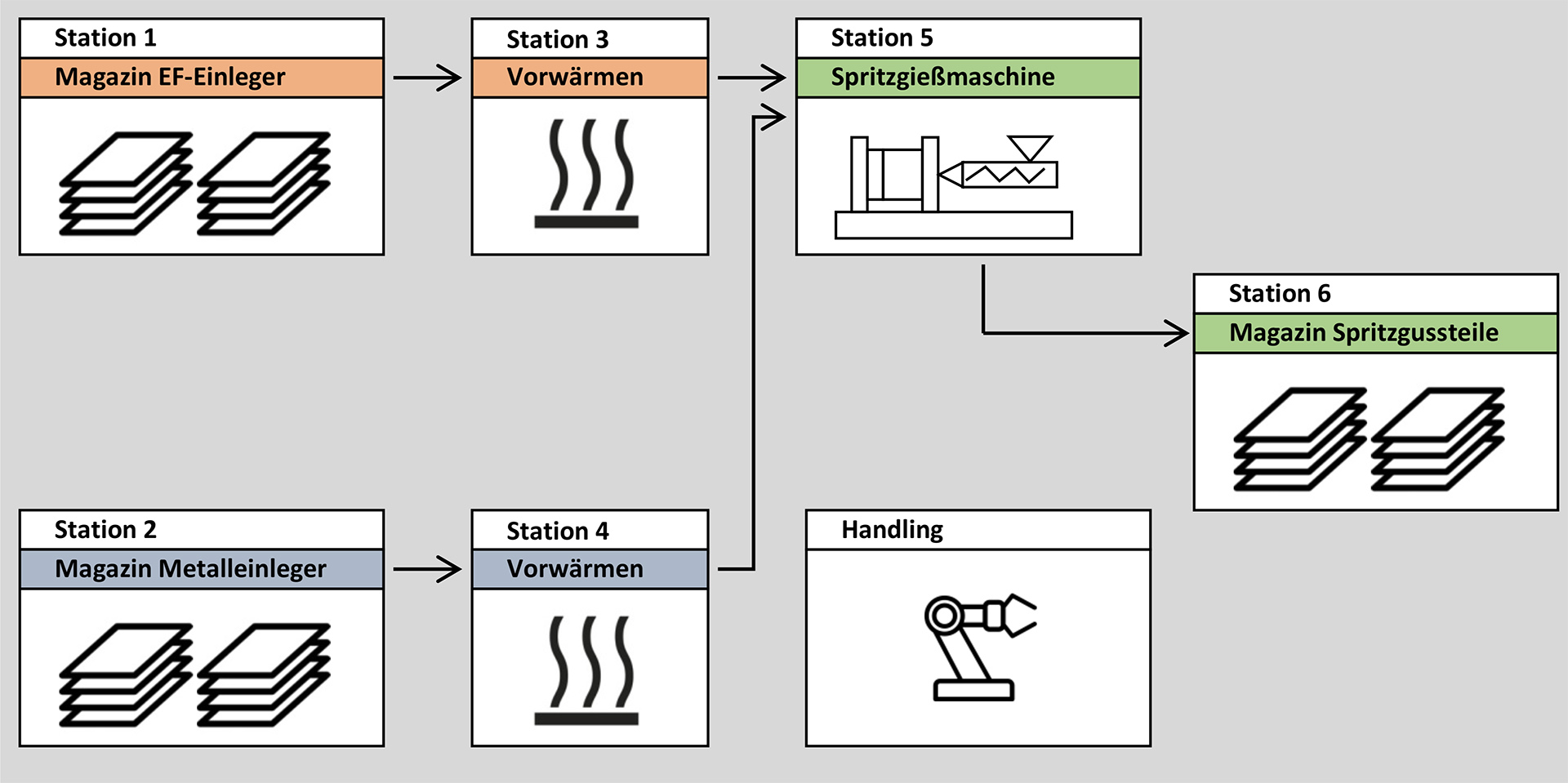

Manufacturing process analysis

In this step, the process chain for the manufacture of the component is analysed and optimised under the following aspects: process steps, production time, technologies available at your site, investment costs, etc. As a result, we develop a concept for a possible process chain with all necessary plant modules for the manufacture of a fibre-reinforced thermoplastic component for you.

10

Prototyping

We are happy to test the jointly developed tool or your externally manufactured tool at the coupon or component level. We determine the optimal manufacturing parameters for you and provide you with comprehensive process documentation.

11

Component testing

In accordance with your component specifications, we draw up a test plan and carry out the necessary component tests, such as:

- Static and dynamic loads

- Temperature behaviour

- Investigation of medial influences and chemical resistance

- Weather resistance (e.g. UV resistance)

- Vibration and acoustic investigations

12

Sustainability

With the increase in lightweight construction potential achieved from our projects and the associated CO2 savings for moving components, we already achieve a high level of sustainability during the use phase. We are happy to develop detailed recycling concepts for your FRP components to ensure sustainability even after the use phase.

13

Recycling

- Shredding of the pure-grade production waste

- Preparation and compounding of the crushed material

- Mechanical and chemical testing of recycled materials

- Production of samples for mechanical characterization of possible components from recyclate

- Investigations into the mechanical degradation of materials in terms of sustainability

Put together your project with us according to your wishes.

You can take advantage of our full-service engineering or call us in at any point in your R&D process. Choose the exact combination of R&D services you need, from conceptual design to pre-series development and component testing.

- Conceptual design for components, manufacturing technologies and plant engineering

- Component design, development and construction with suitable material combinations

- Comprehensive 3D process simulations

- Tool development and design

- Prototyping and small series production together with our partners

- Static and dynamic component testing and validation

- Plant design and implementation with partners from our network