An excerpt of our projects in the field of fibre-reinforced plastics

Development of a component carrier for a battery electric vehicle using continuous fibre-reinforced thermoplastics

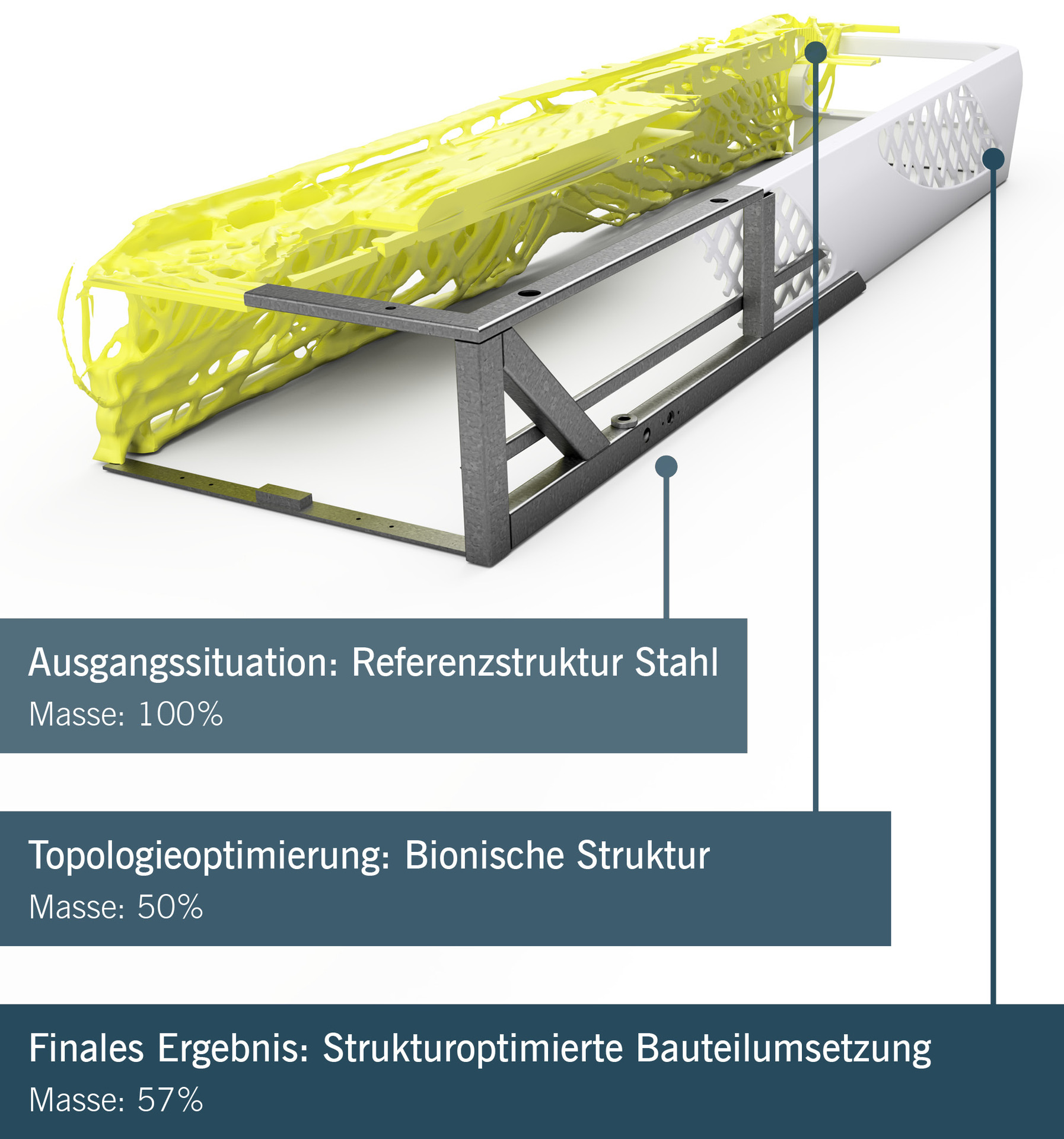

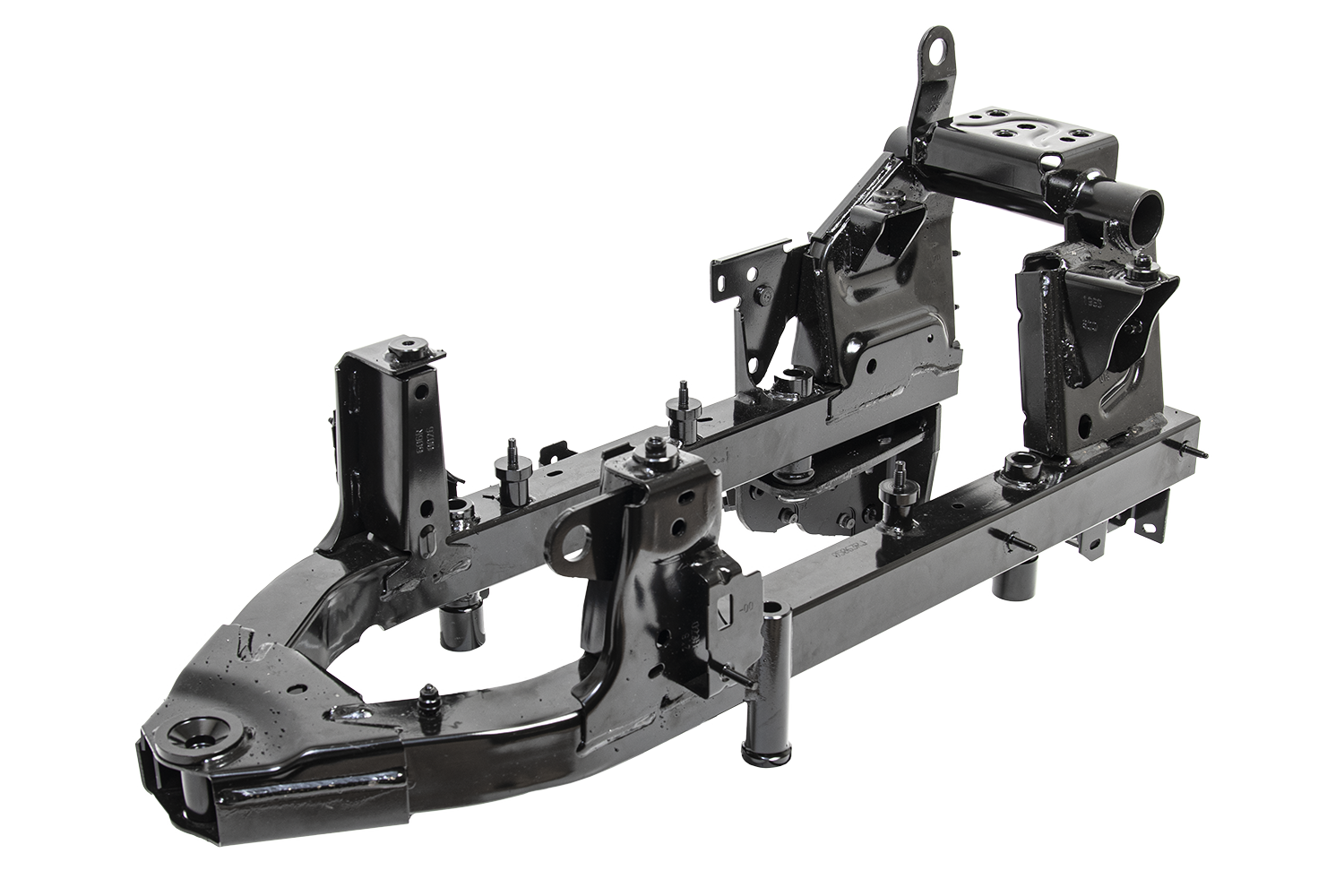

As part of a cooperation between the MAHLE Group and thermoPre ENGINEERING GmbH, a component carrier from an electric vehicle was redesigned with long and continuous fibre-reinforced thermoplastic moulding compounds and a 35 % weight reduction was achieved.

Through the holistic development process, an integrative and load-adapted plastic component was produced that meets the highest requirements in terms of stiffness, strength and lightweight construction. Another advantage of the FRP component: In the event of a crash, a higher energy absorption takes place, which means that there is no abrupt component failure.

Project overview

- Analysis of the component and specifications, development of solutions

- Joint evaluation of the variants and selection of a preferred variant

- Detailing of the component construction incl. stiffness and strength verification

- Tool design and conceptual design of the manufacturing process

- Prototype manufacturing using the press process with fibre-reinforced thermoplastic composites

- Possible series supply by MAHLE

- Duration Stage 1, Engineering: June 2017 - November 2017

- Duration Stage 2, Prototyping: January 2018 - September 2018

- www.mahle.com

Source: thermoPre ENGINEERING

Source: thermoPre ENGINEERING, MAHLE Group

Source: MAHLE Group

Weight reduction compared to steel component

Reduction in production time

Multifunctional lightweight stretcher table for ERVs reduces weight by 43 %

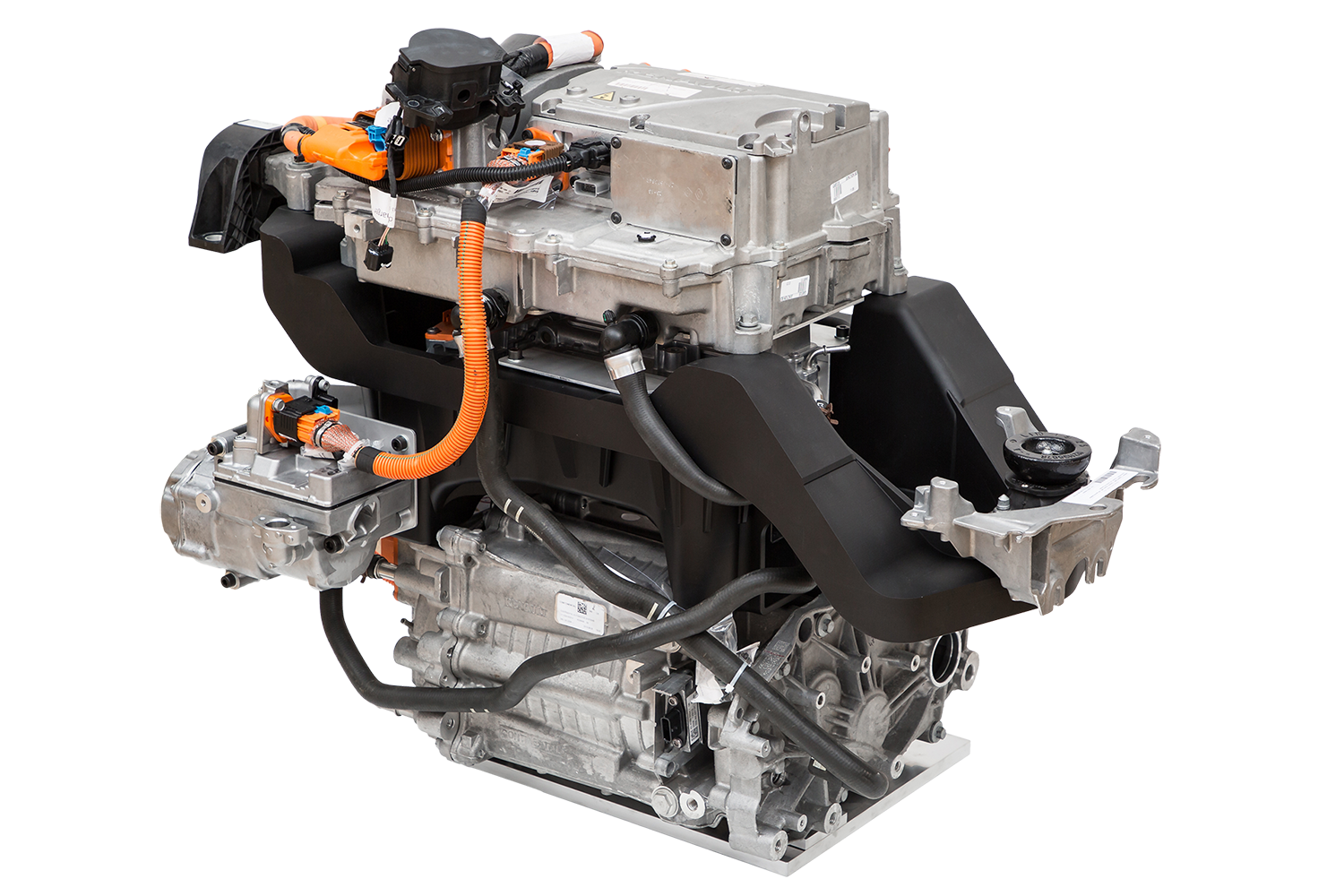

Together with Ambulanz Mobile GmbH & Co. KG, thermoPre ENGINEERING GmbH has developed a new stretcher table for fixing stretchers in ambulances and emergency response vehicles (ERVs). The conventional steel construction was completely redesigned as a plastic component. This made it possible to achieve the goal of using the material primarily along the lines of force flow and thus significantly reduce the overall mass.

Project overview

- Analysis of the actual component and the acting forces

- A topology-optimised bionic structure has already made it possible to reduce the mass by 50 %, resulting in a basic shape with a bionic appearance.

- Subsequently, a further optimisation of the basic shape was carried out according to the force flows

- Validation through FEM analysis

- Product design of the final stretcher table

- Development of a modular storage compartment concept according to customer requirements and application

- Production of the 1:1 model using rapid prototyping and 3D printing

- Duration: January 2019 - May 2019

- www.ambulanzmobile.eu